Micromech’s Systems division is certified to build UL listed industrial control panels.

July 3, 2023 Leave a comment

Micromech’s Systems division has been designing and building bespoke motion control systems for 33 years. A few years ago to expand the wide range of services already offered we went through the process of becoming a UL Listed industrial control panel builder.

This allows us to build and label control panels to UL508a which is suitable for export to the USA and Canada.

Please contact our Systems Director, Mick Stone on 01376 333314 or mstone@micromech.co.uk for more details on this service and how we may able to help you

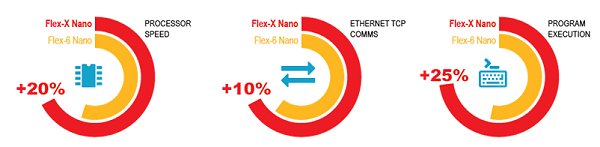

Powerful, compact and flexible, the

Powerful, compact and flexible, the

Motion Safety – The Concept for Safe Motion

Motion Safety – The Concept for Safe Motion Productivity Gains with Motion Safety

Productivity Gains with Motion Safety